Compared with indoor lights, outdoor lights need to withstand the test of icy sun, wind, rain and thunder for a long time. In order to ensure the long-term stable operation of outdoor LEDs under harsh conditions, stadium lights need to have a waterproof design. If there is no high intensity The waterproof design will directly cause internal short circuit and burn directly every rainy season. It is conceivable that only the indicator of waterproof can be a preliminary measure of long-term durability.

Up to now, the waterproof technology of lamps and lanterns is mainly divided into two aspects: structural waterproofing and material waterproofing. The so-called structural waterproofing means that the various structural components of the product are already waterproof after the assembly is completed. The waterproof material is included in the scope of the product design for waterproof work. When assembling, you only need to add waterproof rubber ring and waterproof glue to the reserved position to achieve waterproofing. These two waterproof designs use different product lines, and each has its own advantages.

Ultraviolet rays can damage the wires, protective coatings of the housing, plastic parts, seals and adhesives that are exposed outside the lamp.

After the wire insulation is aging and cracked, water will penetrate into the interior of the lamp through the gap of the wire core. This causes a short circuit to burn the lamp.

The outdoor temperature changes greatly every day, and the surface temperature of the lamp can rise to 50-60°C during the summer. In this high temperature environment, the material is very easy to accelerate the aging. At night, it will reach 10-20°C. In winter, the temperature of ice and snow can drop below zero. Plastic parts become more brittle, and they are easily deformed and cracked under the pressure of ice and snow.

Thermal expansion and contraction of the lamp shell: The change of temperature causes the thermal expansion and contraction of the lamp. The linear expansion coefficients of different materials (such as glass and aluminum profiles) are different, and the two materials will shift at the joint. The process of thermal expansion and contraction is repeated continuously, and the relative displacement is also repeated continuously, which greatly damages the air tightness of the lamp.

The internal air expands with heat and shrinks with cold: the water droplets on the glass of the buried lamp can often be observed on the ground of the square, but how do the water droplets penetrate into the lamps filled with potting glue? This is the result of respiration during thermal expansion and contraction.

Structurally waterproof design lamps need to be closely matched with silicone seals for waterproofing. Generally, the shell structure is designed to be more precise and complex, and the corresponding processing and tolerances will also be more demanding. Usually suitable for lamps with a relatively large size.

Structural waterproof lamps are only assembled with pure mechanical structure, the tools are simple, the assembly procedures and processes are few, the final assembly cycle is short, and the repair on the production line is convenient and quick. The lamps can be packaged and shipped after passing the electrical performance and waterproof test, which is suitable for projects with short delivery periods.

The waterproof design of the material uses filling potting glue to insulate and waterproof, and uses sealant to stick the gaps between the structures. The electrical parts are completely airtight and waterproof.

Whether it is structural waterproofing or material waterproofing, for outdoor lighting needs for long-term stable operation and low failure rate, a single waterproof design is difficult to achieve extremely high reliability, nor can it meet all application scenarios. Therefore, high-end outdoor LED lighting design uses flexible waterproof design, combining the advantages of the two, to maximize the advantages and avoid the disadvantages, to ensure the long-term stable operation of the LED circuit.

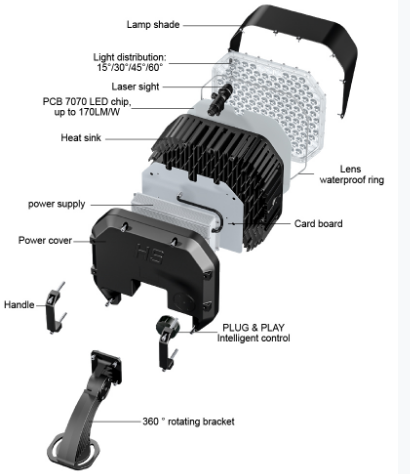

Hi-Shoot's outdoor sports light combines the waterproof of the two, which can better cope with more usage scenarios

Author 2025-06-12

Hishine Group Limited Will Meet Customers In Mexico City.Hishine is thrilled to announce its participation in Expo Eléctrica International 2025, Latin America’s premier trade fair for power and lighti...

Author 2025-05-12

Our recent business trip to Saudi Arabia proved to be a pivotal step in strengthening partnerships and exploring opportunities in the Kingdom’s rapidly growing energy and lighting markets. Below are t...