After the above comparison, you should have decided on a suitable lamp. Let’s talk about color temperature. Under normal circumstances, color temperature does not seem to be an important thing to consider, but it can have a huge impact on light visibility and productivity. The color temperature between 4000k-5000k is the best choice for warehouses. This color temperature can emit cool white and is sometimes regarded as having a blue hue. This has been proven in research to help reduce eye fatigue and create a productive working environment. For example, many scenes use cool white. Hospitals, office buildings, etc.

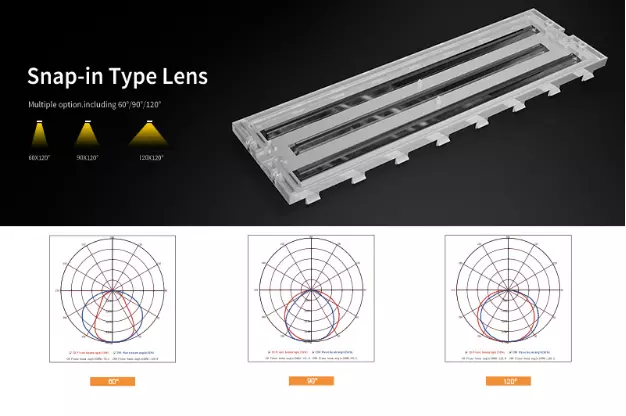

Which type of light distribution should be used?

Warehouses usually require two types of light distribution. One type of I or V, the specific need depends on the layout of the facility. Spaces with overhead units require Type I, which is a very long and slender light pattern. This ensures that no light is lost or blocked by the top of the shelf. If your warehouse has a more open floor plan, the V-shaped light distribution is more appropriate. This light pattern emits wide-angle light from all sides of the luminaire in a circular or square distribution. Learn more about the difference in light modes,

The spacing of the lamps is very important. If they are located too close, you will experience hot spots and/or glare, where the light from one fixture overlaps the next. If their locations are too far apart, you will get lighting "descent" or dark areas. Before purchasing or installing, be sure to determine the location of your lamps.

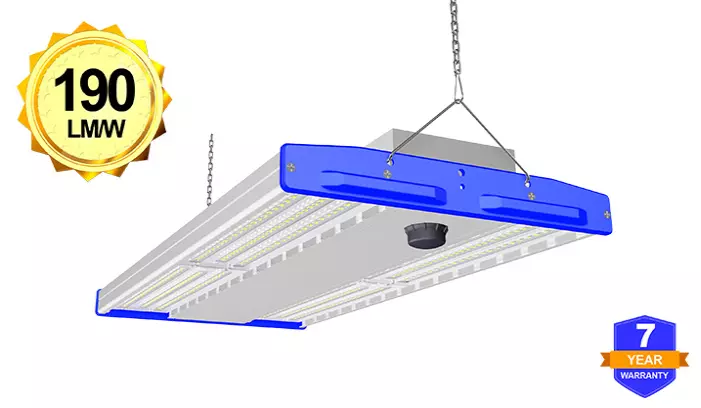

The length of the life of the lamp directly determines the probability of a subsequent repair, which affects the logistics of the warehouse and the efficiency of the workers, and also affects the efficiency of shipments and profitability. In order to avoid an increase in maintenance costs in the future. It is necessary to choose warehouse lights with long life and high stability.

Our LED Linear Warehouse Light supports infrared remote control, ZigBee, Bluetooth mesh network, high altitude microwave sensor, infrared light sensor. The ZigBee version also supports heat map function and light decay compensation. Can greatly improve the maximum efficiency of personnel.

In the lighting of large spaces such as warehouses, occupancy and vacancy rate sensors can be your best friends. Adding one of these motion sensor types to your lighting design can reduce energy waste costs by up to 30% without the need for major updates. These sensors turn the lights on and/or off based on whether someone is in the space. When you want the lights to turn on and off automatically, use an occupancy sensor. Vacancy sensors are suitable for areas that do not need to turn on the lights every time someone enters, such as warehouses with large skylights to illuminate the space, but you still want them to turn off when the space is empty

Author 2025-06-12

Hishine Group Limited Will Meet Customers In Mexico City.Hishine is thrilled to announce its participation in Expo Eléctrica International 2025, Latin America’s premier trade fair for power and lighti...

Author 2025-05-12

Our recent business trip to Saudi Arabia proved to be a pivotal step in strengthening partnerships and exploring opportunities in the Kingdom’s rapidly growing energy and lighting markets. Below are t...